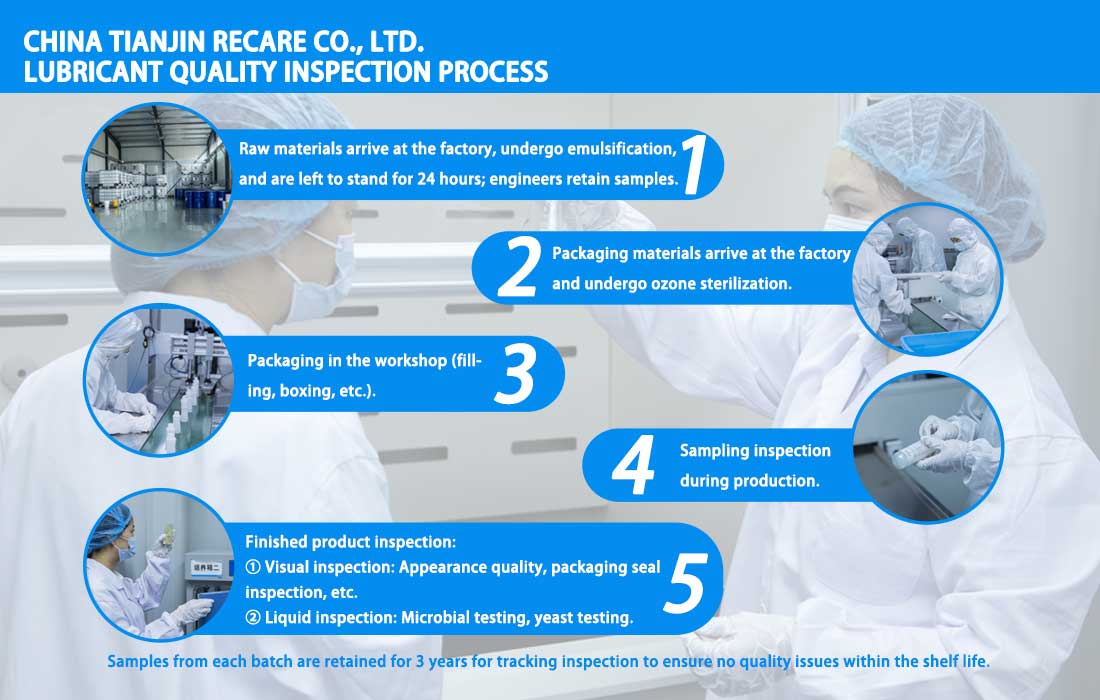

Lubricant Quality Inspection Process

China Tianjin Recare Co.Ltd. focus on manufacturing love lube, lubricant for sexual activity and top personal lubricants. And always prioritize product quality and safety, relying on strict international standards to ensure the superior quality of every drop of safe at home lube.

After raw materials enter the factory, they undergo multiple rounds of testing in a 10,000-level purification laboratory to guarantee their purity and biological safety—essential steps in crafting a reliable love lube. The core production processes are then carried out in a 100,000-level cleanroom to avoid any risk of contamination throughout manufacturing.

We have our own laboratory that meets international standards, conducting full tests on each batch of love lube products, including pH value, viscosity, microbial limits, and stability, while strictly adhering to the requirements of management systems such as ISO9001. All quality inspection processes are jointly supervised by 15 professional personnel and a postdoctoral advisor team, with data meticulously recorded through a traceable system.

Based on our whole batch quality control capabilities and certification system,we can provide customers with TUV third-party test reports to objectively verify product safety with internationally recognized data. From R&D customization to whole batch production, we adhere to strict standards, ensuring that every lubricant for sexual intercourse activity delivered is stable and reliable, to produce the best rated lube.